- WEDGE ANCHORS

- NYLON HAMMER ANCHOR

- DROP IN ANCHORS

- NYLON NAIL ANCHOR

- SLEEVE ANCHOR LONG HOL

- ZINC ALLOY HAMMER DRIV

- SLEEVE ANCHOR ROUND HO

- TAM ANCHOR

- SLEEVE ANCHOR ABC :1.N

- HIT ANCHOR

- SLEEVE ANCHOR ABC: 1.H

- TWO SHIELD ANCHOR

- CHEMICAL ANCHOR STUD

- THREE SHIELD ANCHOR

- PJ ANCHOR

- FOUR SHIELD ANCHOR

- HEAVY DUTY RODS AND HE

- CEILING ANCHOR

- BOLT ANCHOR

- TOGGLE WING

Products

-

Product name: WEDGE ANCHORS

Hits: 10887 Category: WEDGE ANCHORS Model:

Product details

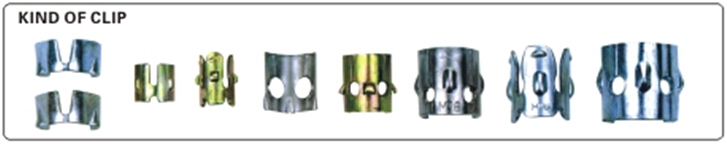

1.BOLT IS USING COLD FORMING UNTIL M24x300,1"x12"EDGE OF CLIP HAVE DEGREE TO MAKE SURE EASY TO EXPAND THE CLIP OF THE WEDGE ANCHOR FORMED ARROUND ANCHOR ASSURING FULL EXPANSION FOR SUPERIOR HOLDING POWER, DEPENDABLE.

2.MEDIUM AND HIGH DUTY APPLICATION.

3.AVAILABLE IN CARBON STEEL AND STAINLESS STEEL MATERIAL.

4.COLD FORMING SYSTEM, BY USING NEW ONE FORMING TECHNIQUE WE ARE ABLE TO MAKE THE BEST QUALITY FOR A VERY SMOOTH EXPANSION DEGREE TO ENSURE THE ANCHOR EXPAND WELL ON THE CONCRETE.

| WEDGE ANCHOR ( Plating Thickness 3-5 um ) | ||||||||

| CODE NO | SIZE | THREAD | MAXIMALFAST THICKNESS (mm) | ANCHORLENGTH (mm) | DRILL HOLEФmm | MIN HOLEDEPTH mm | ANCHOR WEIGHT KGS/1000PCS | PACKING BOX/CTN |

| WA-06-40 | M6X40 | M6 | 3 | 40 | 6 | 35 | 9.92 | 200/2000 |

| WA-06-70 | M6X70 | M6 | 30 | 70 | 6 | 50 | 15.06 | 150/1500 |

| WA-08-60 | M8X60 | M8 | 20 | 60 | 8 | 55 | 24.50 | 200/1000 |

| WA-08-70 | M8X70 | M8 | 30 | 70 | 8 | 55 | 27.67 | 150/750 |

| WA-08-80 | M8X80 | M8 | 40 | 80 | 8 | 55 | 30.24 | 150/750 |

| WA-08-90 | M8X90 | M8 | 50 | 90 | 8 | 55 | 33.02 | 120/600 |

| WA-08-100 | M8X100 | M8 | 60 | 100 | 8 | 55 | 36.60 | 120/600 |

| WA-10-80 | M10X80 | M10 | 20 | 80 | 10 | 70 | 51.72 | 80/400 |

| WA-10-95 | M10X95 | M10 | 35 | 95 | 10 | 70 | 59.44 | 80/400 |

| WA-10-120 | M10X120 | M10 | 60 | 120 | 10 | 70 | 70.60 | 50/250 |

| WA-12-70 | M12X70 | M12 | 4 | 70 | 12 | 65 | 69.86 | 60/300 |

| WA-12-80 | M12X80 | M12 | 10 | 80 | 12 | 75 | 77.28 | 50/250 |

| WA-12-90 | M12X90 | M12 | 20 | 90 | 12 | 80 | 83.82 | 50/250 |

| WA-12-100 | M12X100 | M12 | 30 | 100 | 12 | 80 | 90.78 | 50/250 |

| WA-12-110 | M12X110 | M12 | 40 | 110 | 12 | 80 | 97.30 | 50/250 |

| WA-12-120 | M12X120 | M12 | 50 | 120 | 12 | 80 | 104.14 | 40/200 |

| WA-12-130 | M12X130 | M12 | 60 | 130 | 12 | 80 | 110.93 | 40/200 |

| WA-12-140 | M12X140 | M12 | 70 | 140 | 12 | 80 | 116.68 | 40/200 |

| WA-16-100 | M16X100 | M16 | 5 | 100 | 16 | 95 | 166.60 | 30/150 |

| WA-16-140 | M16X140 | M16 | 40 | 140 | 16 | 110 | 221.35 | 20/100 |

| WA-16-145 | M16X145 | M16 | 45 | 145 | 16 | 110 | 225.70 | 20/100 |

| WA-16-150 | M16X150 | M16 | 50 | 150 | 16 | 110 | 231.62 | 20/100 |

| WA-20-120 | M20X120 | M20 | 10 | 120 | 20 | 115 | 306.05 | 15/75 |

| WA-20-130 | M20X130 | M20 | 20 | 130 | 20 | 120 | 339.00 | 15/75 |

| WA-24-160 | M24X160 | M24 | 40 | 160 | 24 | 120 | 586.90 | 8/40. |

| WA-24-300 | M24X300 | M24 | 150 | 300 | 24 | 120 | 1231.80 | 5/20. |

| CODENO | SIZE | THREAD | MAXIMALFAST THICKNESS (mm) | ANCHORLENGTH (mm) | DRILL HOLEФmm | MIN HOLEDEPTH mm | ANCHOR WEIGHT KGS/1000PCS | PACKINGBOX/CTN |

| WA-14134 | 1/4X1-3/4 | 1/4 | 1/8 | 1-3/4 L | Ф1/4 | 1-1/8 L | 13.11 | 200/2000 |

| WA-14214 | 1/4X2-1/4 | 1/4 | 3/8 | 2-1/4 L | Ф1/4 | 1-1/8 L | 15.57 | 150/1500 |

| WA-516234 | 5/16X2-3/4 | 5/16 | 9/16 | 2-3/4 L | Ф5/16 | 1-1/2 L | 27.12 | 150/750 |

| WA-516312 | 5/16X3-1/2 | 5/16 | 1--1/8 | 3-1/2 L | Ф5/16 | 1-1/2 L | 33.46 | 120/600 |

| WA-38234 | 3/8X2-3/4 | 3/8 | 3/8 | 2-3/4 L | Ф3/8 | 1-1/2 L | 39.99 | 100/500 |

| WA-38300 | 3/8X3 | 3/8 | 9/16 | 3 | Ф3/8 | 1-1/2 L | 43.12 | 100/500 |

| WA-38334 | 3/8X3-3/4 | 3/8 | 1--1/8 | 3-3/4 L | Ф3/8 | 1-1/2 L | 50.21 | 100/500 |

| WA-12234 | 1/2X2-3/4 | 1/2 | 1/8 | 2-3/4 L | Ф1/2 | 2 | 76.71 | 60/300 |

| WA-12414 | 1/2X4-1/4 | 1/2 | 3/4 | 4-1/4 L | Ф1/2 | 2-1/4 L | 107.79 | 40/200 |

| WA-12512 | 1/2X5-1/2 | 1/2 | 2 | 5-1/2 L | Ф1/2 | 2-1/4 L | 130.79 | 40/200 |

| WA-58312 | 5/8X3-1/2 | 5/8 | 1/8 | 3-1/2 L | Ф5/8 | 2-3/4 L | 152.11 | 30/150 |

| WA-58412 | 5/8X4-1/2 | 5/8 | 9/16 | 4-1/2 L | Ф5/8 | 2-3/4 L | 183.84 | 25/125 |

| WA-34512 | 3/4X5-1/2 | 3/4 | 1--5/16 | 5-1/2 L | Ф3/4 | 3-1/4 L | 321.36 | 15/75 |

| WA-34614 | 3/4X6-1/4 | 3/4 | 1--3/4 | 6-1/4 L | Ф3/4 | 3-1/4 L | 359.66 | 15/75 |

| WA-78600 | 7/8X6 | 7/8 | 1--3/4 | 6 | Ф7/8 | 3-1/4 L | 487.13 | 5/25. |

| WA-781200 | 7/8X12 | 7/8 | 2 | 12 | Ф7/8 | 9 | 945.90 | 5/20. |

| WA-01600 | 1X6 | 1" | 1--3/4 | 6 | Ф1 | 3-1/4 L | 656.29 | 8/40. |

| WA-011200 | 1X12 | 1" | 2 | 12 | Ф1 | 9 | 1150.75 | 5/20. |

STAINLESS STEEL AND SPECIAL LENGTH IS AVAILABLE

| SIZE mm | MATERIAL SIZE Ф mm | TORGUE WRENCH Nm | TENSILE STRENGTH σь (Mpa) | SHEAR STRENGTH τb (Mpa) | SAFETY PULL OUT LOAD KGS |

| M6 | 5.13 | 12 | 613 | 372 | 920 |

| M8 | 6.85 | 16 | 598 | 375 | 1200 |

| M10 | 8.75 | 35 | 596 | 379 | 1600 |

| M12 | 10.56 | 55 | 586 | 362 | 2600 |

| M16 | 14.36 | 100 | 573 | 361 | 3800 |

| M20 | 17.97 | 150 | 549 | 368 | 4900 |

| M24 | 21.61 | 180 | 533 | 363 | 7000 |

| INSTALLATION OF PULL OUT LOAD |

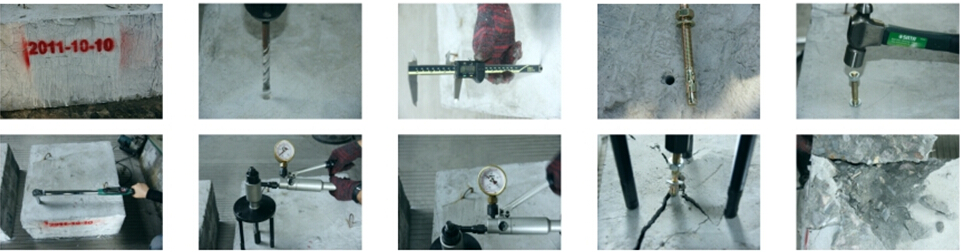

| 1. 5 pcs Anchor for Testing. |

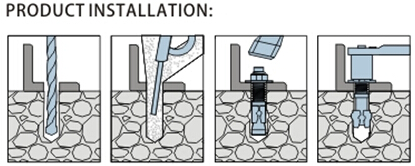

| 2. Drill a hole. |

| 3. Measure hole depth. |

| 4. Clean the hole, prepare Anchor. |

| 5. Put the Anchor in the hole by Hammering. |

| 6. Using Torque Wrench to fast the Anchor ( Nm ). |

| 7. Installed Pull out Load Machine. |

| 8. Start to Pull out the Anchor. |

| 9. See the Pull out Load Strength when the concrete is Broken. |

| 10.The concrete will Broken when the Anchor is Pull out. |

FINAL TEST REPORT OF PULL OUT LOAD |

|  | ||||||||||||||||||||||||||||||||

Copyright © 2015 Ningbo ABC Fasteners Co.,Ltd All Rights Reserved Design by Hozest

NINGBO ABC FASTENERS CO., LTD

Website:www.abc-fasteners.com